Address

| Availability: | |

|---|---|

| Quantity: | |

DIN1624

YPH

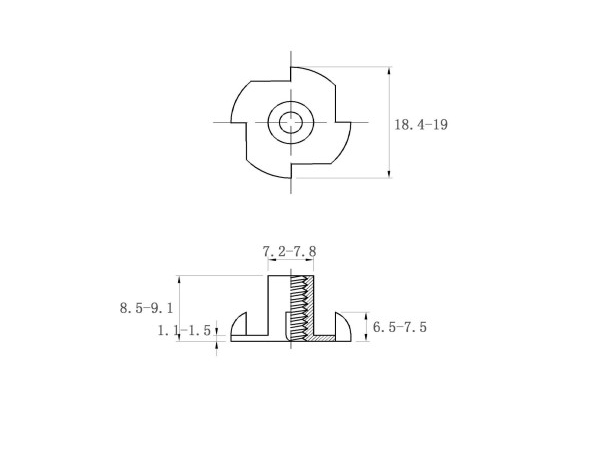

The DIN1624 tee nuts with pronge is a specialized fastening nut independently developed by YPH, featuring a unique four-claw design for secure embedded installation. Made of high-quality stainless steel or carbon steel, it is tailored for wooden and composite materials, where the prongs can be firmly embedded into the substrate to prevent nut rotation during screw tightening. With two surface treatment options of passivation and zinc plating, it achieves excellent corrosion resistance while adapting to different application environments. Its compact T-shaped structure enables hidden installation, making it an ideal fastening solution for furniture and woodworking projects that require aesthetic appearance and stable performance.

Item | Details |

Standard | DIN1624 |

Material | Stainless steel, Carbon steel |

Size Range | M4–M10 |

Surface Treatment | Passivate, Zincplated |

Pronge Quantity | 4 |

Applicable Substrate | Wood, Composite materials |

Brand | YPH |

The four prongs can bite into the substrate tightly, effectively preventing the nut from spinning when the screw is tightened, and ensuring reliable connection.

Stainless steel versions are suitable for corrosion-prone environments, while carbon steel zinc-plated versions offer cost-effectiveness, meeting different budget and usage requirements.

The T-shaped structure can be fully embedded into the substrate, leaving no protrusions on the surface and maintaining the integrity of the product appearance.

Used for assembling wardrobes, desks, chairs, and beds, realizing hidden fastening of furniture panels and ensuring firm and durable connections.

Applied in custom wooden shelves, cabinets, and decorative crafts, adapting to the characteristics of wooden materials and avoiding splitting of the substrate.

Suitable for installing light-duty industrial racks, workbench fixtures, and display stands, providing stable load-bearing capacity for long-term use.

Drill a hole matching the nut size on the substrate, then insert the tee nut and press it firmly to make the prongs fully embed into the wood.

Cooperate with machine screws of the same specification for installation; avoid over-tightening to prevent damage to the substrate or threads.

For outdoor wooden structures, choose the stainless steel passivation version to enhance corrosion resistance.

Inquiry Service: Provide detailed size parameters and usage scenarios to get accurate quotes and delivery cycles.

Minimum Order Quantity: Flexible MOQ to meet both small-batch trial and large-batch procurement needs.

After-Sales Support: Professional technical guidance is available for installation problems during use.

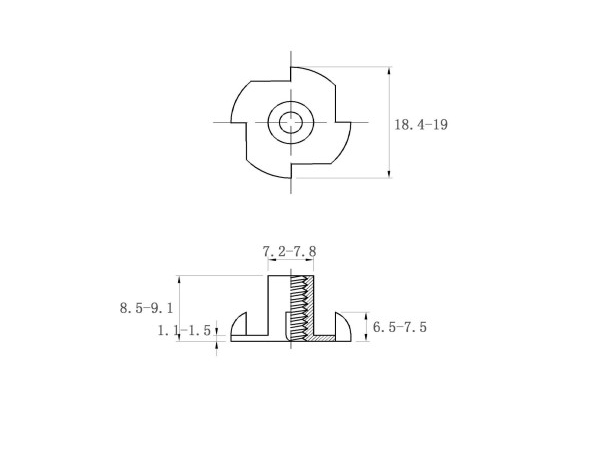

The DIN1624 tee nuts with pronge is a specialized fastening nut independently developed by YPH, featuring a unique four-claw design for secure embedded installation. Made of high-quality stainless steel or carbon steel, it is tailored for wooden and composite materials, where the prongs can be firmly embedded into the substrate to prevent nut rotation during screw tightening. With two surface treatment options of passivation and zinc plating, it achieves excellent corrosion resistance while adapting to different application environments. Its compact T-shaped structure enables hidden installation, making it an ideal fastening solution for furniture and woodworking projects that require aesthetic appearance and stable performance.

Item | Details |

Standard | DIN1624 |

Material | Stainless steel, Carbon steel |

Size Range | M4–M10 |

Surface Treatment | Passivate, Zincplated |

Pronge Quantity | 4 |

Applicable Substrate | Wood, Composite materials |

Brand | YPH |

The four prongs can bite into the substrate tightly, effectively preventing the nut from spinning when the screw is tightened, and ensuring reliable connection.

Stainless steel versions are suitable for corrosion-prone environments, while carbon steel zinc-plated versions offer cost-effectiveness, meeting different budget and usage requirements.

The T-shaped structure can be fully embedded into the substrate, leaving no protrusions on the surface and maintaining the integrity of the product appearance.

Used for assembling wardrobes, desks, chairs, and beds, realizing hidden fastening of furniture panels and ensuring firm and durable connections.

Applied in custom wooden shelves, cabinets, and decorative crafts, adapting to the characteristics of wooden materials and avoiding splitting of the substrate.

Suitable for installing light-duty industrial racks, workbench fixtures, and display stands, providing stable load-bearing capacity for long-term use.

Drill a hole matching the nut size on the substrate, then insert the tee nut and press it firmly to make the prongs fully embed into the wood.

Cooperate with machine screws of the same specification for installation; avoid over-tightening to prevent damage to the substrate or threads.

For outdoor wooden structures, choose the stainless steel passivation version to enhance corrosion resistance.

Inquiry Service: Provide detailed size parameters and usage scenarios to get accurate quotes and delivery cycles.

Minimum Order Quantity: Flexible MOQ to meet both small-batch trial and large-batch procurement needs.

After-Sales Support: Professional technical guidance is available for installation problems during use.